How to Choose a Soft Close Toilet Seat Manufacturer: A Practical OEM Buyer’s Guide

Choosing the right soft close toilet seat manufacturer is a critical decision for OEM buyers, wholesalers, and private label brands.

While many suppliers can offer similar-looking products, differences in hinge quality, production consistency, and OEM capability often determine long-term success or repeated sourcing problems.

This guide explains how buyers can systematically evaluate and select a reliable soft close toilet seat manufacturer, avoiding common mistakes and reducing sourcing risks.

Why Manufacturer Selection Matters for OEM Buyers

For OEM projects, the manufacturer directly affects:

- Product performance and lifespan

- Consistency between samples and bulk orders

- Brand reputation in retail or project markets

- After-sales issues and replacement costs

Many sourcing problems occur not because of price, but because buyers choose suppliers without fully evaluating manufacturing capability. Reviewing verified factories—such as those listed in our Top 20 Soft Close Toilet Seat Manufacturers—is often the first step toward a safer sourcing decision.

5 Key Factors to Evaluate a Soft Close Toilet Seat Manufacturer

1. Soft Close Hinge Durability

The hinge is the core component of any soft close toilet seat.

A professional manufacturer should be able to demonstrate:

- Stable damping speed after repeated use

- No oil leakage or abnormal noise

- Consistent performance across different production batches

Buyers should ask how hinges are tested and whether the manufacturer controls hinge assembly in-house or relies on external suppliers.

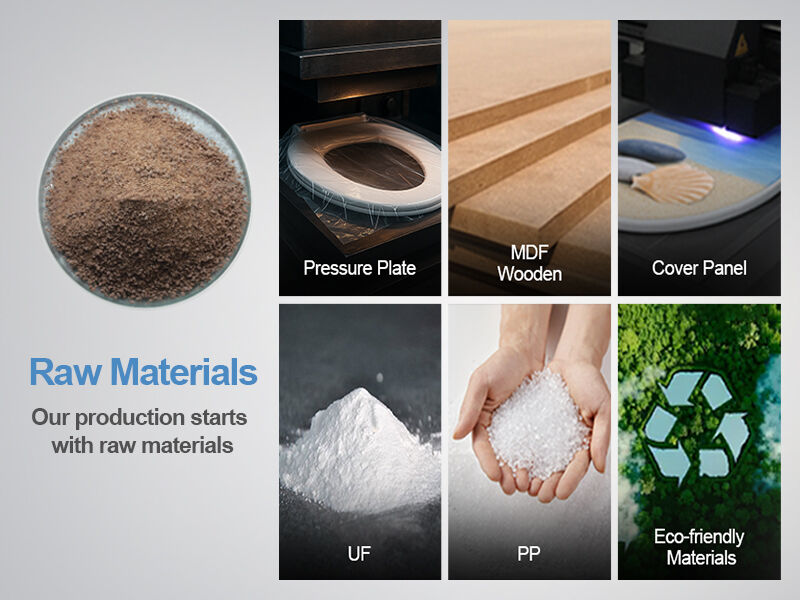

2. Material Compatibility with Target Markets

Different markets prefer different materials, and not all factories handle every material equally well.

Common options include:

- UF (Duroplast): Durable, scratch-resistant, premium appearance

- PP (Polypropylene): Lightweight, cost-efficient, easy maintenance

- MDF / Wooden finishes: Decorative, retail-focused designs

A reliable soft close toilet seat manufacturer should guide buyers on material selection based on market regulations, price positioning, and end-user expectations.

3. OEM & Customization Capability

OEM buyers rarely want identical products to competitors.

Key customization capabilities to evaluate include:

- Logo engraving or printing

- Custom packaging and manuals

- Adjustable hinge specifications

- Mold development for exclusive designs

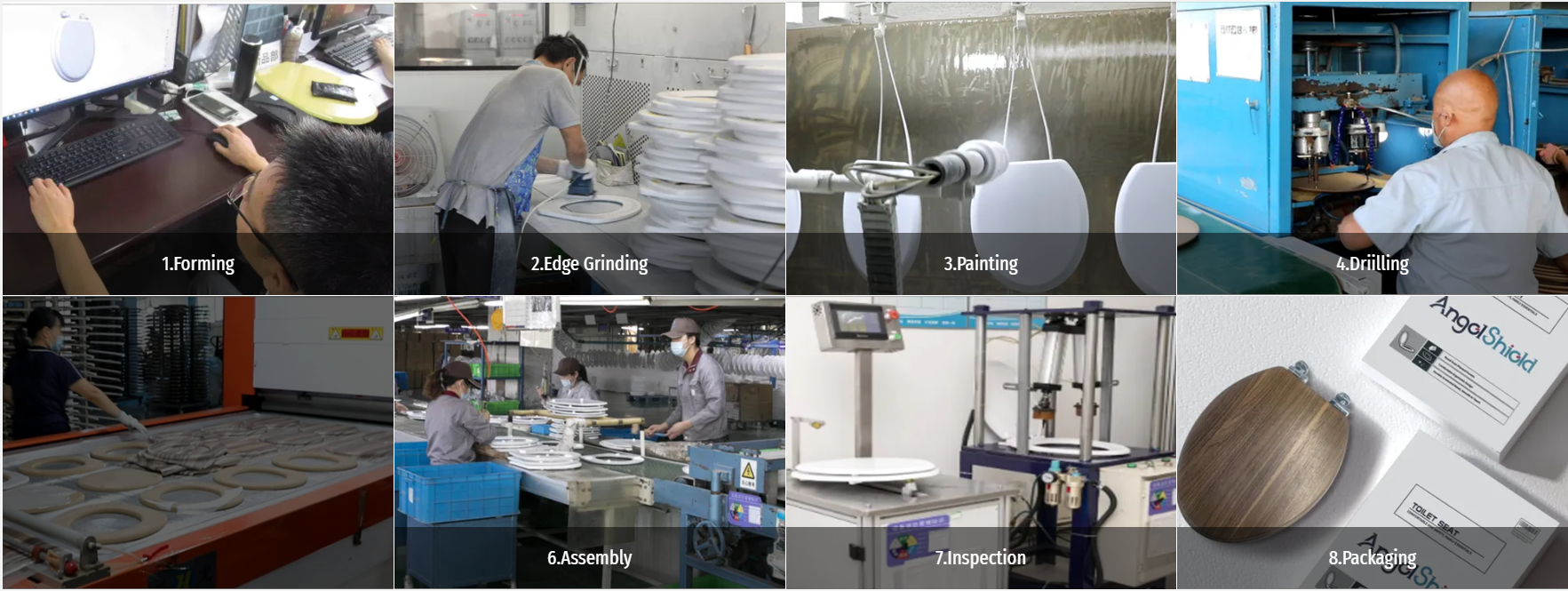

Manufacturers with strong OEM experience typically offer structured workflows for sampling, confirmation, and mass production—reducing miscommunication during projects.

4. Quality Control & Certifications

Quality control is what ensures bulk production matches approved samples.

Buyers should confirm whether the manufacturer has:

- Incoming material inspection

- Soft close performance testing

- Final inspection before packing

- Recognized certifications (ISO, CE, UPC, etc.)

Even simple quality systems can significantly reduce defect rates if applied consistently.

5. Delivery Reliability & Long-Term Cooperation

Beyond the first order, long-term cooperation depends on:

- Stable lead times

- Clear communication

- Willingness to support repeat or upgraded orders

Experienced OEM buyers often prefer manufacturers that focus on long-term partnerships rather than one-time transactions.

Common Mistakes Buyers Make When Choosing Suppliers

Many sourcing issues come from predictable mistakes, such as:

- Choosing suppliers based solely on the lowest price

- Ignoring hinge quality during sampling

- Not confirming MOQ and customization limits early

- Assuming all manufacturers offer the same OEM support

Avoiding these mistakes can save months of delays and unexpected costs.

A Practical Checklist Before Sending an Inquiry

Before contacting a soft close toilet seat manufacturer, buyers should prepare:

- Target market and certification requirements

- Preferred material and seat shape

- Estimated annual order volume

- Customization needs (logo, packaging, hinge type)

- Expected delivery timeline

Clear requirements help manufacturers provide accurate quotations and realistic lead times.

Many sourcing problems occur because buyers contact too many unverified suppliers.

How Shortlisting Manufacturers Reduces Sourcing Risk

Instead of contacting dozens of suppliers, many buyers first shortlist manufacturers with proven export and OEM experience.

Using an industry overview—such as our Top 20 Soft Close Toilet Seat Manufacturers—allows buyers to compare factories by capability, not just pricing, and focus discussions on technical and commercial feasibility.

Final Thoughts

Selecting the right soft close toilet seat manufacturer is a strategic decision that affects product quality, brand image, and supply stability.

By evaluating hinge durability, material expertise, OEM capability, quality control, and delivery reliability, buyers can confidently choose manufacturing partners that support long-term growth rather than short-term savings.

For buyers starting their sourcing process, reviewing established manufacturers and requesting samples is the most effective next step.